- January 11, 2024

- Gulf Gas

- 0 Comments

- 144 Views

- 6 Likes

- Design

Top 5 Factors to Consider Before LPG Pipeline Installation

Introduction

Liquefied Petroleum Gas (LPG) is a widely used and versatile energy source, employed for various applications such as heating, cooking, and industrial processes. As the demand for LPG continues to grow, the installation of pipelines for its transportation has become increasingly common. However, the installation of LPG pipelines requires careful consideration of several factors to ensure safety, efficiency, and compliance with regulations. In this article, we will explore the top five factors that should be taken into account before LPG pipeline installation.

1. Regulatory Compliance:

Before embarking on any LPG pipeline installation project, it is imperative to thoroughly understand and comply with local, national, and international regulations governing the transportation and handling of LPG. Different regions may have specific safety codes, environmental standards, and construction requirements that must be adhered to. Engaging with regulatory authorities and obtaining the necessary permits is crucial to ensure that the installation meets all legal and safety standards.

2. Risk Assessment and Safety Measures:

Safety should be a top priority in any LPG pipeline installation project. Conducting a comprehensive risk assessment is essential to identify potential hazards and implement appropriate safety measures. Factors such as proximity to residential areas, environmental sensitivity, and geological considerations should be taken into account. Adequate safety features, including emergency shutdown systems, leak detection, and firefighting equipment, must be integrated into the pipeline design to mitigate risks and respond promptly to any unforeseen incidents.

3. Environmental Impact:

The environmental impact of LPG pipeline installation cannot be overlooked. It is essential to assess the potential effects on ecosystems, water bodies, and air quality. Implementing environmentally friendly practices, such as minimizing ground disruption during construction and utilizing advanced technologies to reduce emissions, can contribute to a more sustainable installation. Additionally, measures to prevent and respond to accidental releases of LPG must be in place to protect the environment and surrounding communities.

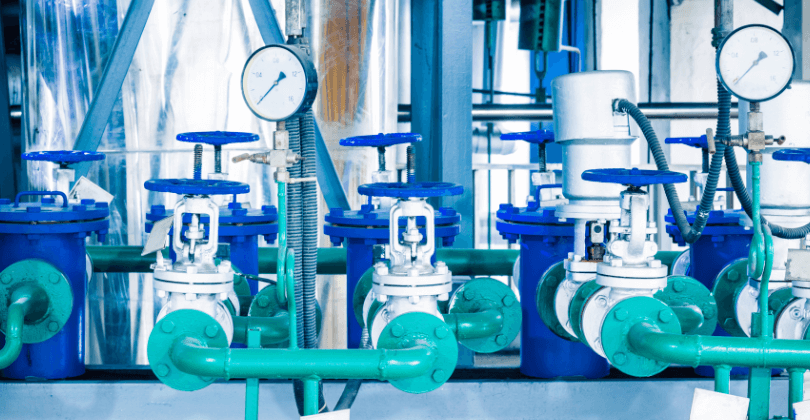

4. Pipeline Material and Design:

The choice of pipeline material and design is a critical factor that influences the efficiency and longevity of the LPG transportation system. Different materials, such as carbon steel, stainless steel, or plastic, may be suitable depending on factors like corrosiveness of the LPG, soil conditions, and operating pressures. The pipeline design should also account for factors like expansion and contraction, seismic considerations, and future maintenance requirements. Engaging with experienced pipeline engineers and experts can help in selecting the most appropriate material and design for the specific project.

5. Project Cost and Economic Viability:

A thorough economic analysis is essential to determine the overall cost of the LPG pipeline installation project. This analysis should include not only the initial construction costs but also ongoing operational and maintenance expenses. Evaluating the economic viability of the project involves considering factors such as the expected lifespan of the pipeline, potential revenue from LPG transportation, and the impact on local economies. Balancing cost-effectiveness with the need for quality and safety is crucial to ensure the long-term success of the LPG pipeline installation.

Conclusion:

LPG pipeline installation is a complex and multifaceted process that requires careful consideration of various factors. By prioritizing regulatory compliance, safety, environmental impact, pipeline material and design, and economic viability, stakeholders can contribute to the successful implementation of LPG transportation systems. Engaging with experienced professionals, conducting thorough risk assessments, and staying abreast of industry best practices are essential steps in ensuring the safe and efficient installation of LPG pipelines.